Handy Links

SLAC News Center

SLAC Today

- Subscribe

- Archives: Feb 2006-May 20, 2011

- Archives: May 23, 2011 and later

- Submit Feedback or Story Ideas

- About SLAC Today

SLAC News

Lab News

- Interactions

- Lightsources.org

- ILC NewsLine

- Int'l Science Grid This Week

- Fermilab Today

- Berkeley Lab News

- @brookhaven TODAY

- DOE Pulse

- CERN Courier

- DESY inForm

- US / LHC

SLAC Links

- Emergency

- Safety

- Policy Repository

- Site Entry Form

- Site Maps

- M & O Review

- Computing Status & Calendar

- SLAC Colloquium

- SLACspeak

- SLACspace

- SLAC Logo

- Café Menu

- Flea Market

- Web E-mail

- Marguerite Shuttle

- Discount Commuter Passes

-

Award Reporting Form

- SPIRES

- SciDoc

- Activity Groups

- Library

Stanford

Around the Bay

Electrons in Hot Water

SLAC's two-mile linear accelerator, with all its klystrons and vacuum chambers, is ultimately committed to one thing—producing beams of high-energy electrons and positrons. But once the scientific usefulness of those beams is exhausted, after the pulses of electrons have collided with positrons or zapped into a research instrument, what do you do with all the left-over energy? The best, time-tested solution, it turns out, is to make hot water.

SLAC's two-mile linear accelerator, with all its klystrons and vacuum chambers, is ultimately committed to one thing—producing beams of high-energy electrons and positrons. But once the scientific usefulness of those beams is exhausted, after the pulses of electrons have collided with positrons or zapped into a research instrument, what do you do with all the left-over energy? The best, time-tested solution, it turns out, is to make hot water.

Back in the early 1960s, before researchers could switch on SLAC's linear accelerator (linac) for the first time, physicists and engineers had to figure out what to do with the beam at the end of its two-mile ride. The old way of stopping a beam involved using a dense barrier like a lead brick or a copper plate to absorb the flow of electrons, but that was simply not enough to dissipate the millions of watts contained in the new beam.

A solution was found in a special device that could soak up the power without overheating and while containing the radiation produced. Called a “beam dump,” this device was invented especially for this purpose by SLAC physicist Dieter Walz. The problem with older “beam catchers” or “beam stops,” as they were referred to, was the intense heat produced as the accelerated electrons passed directly into those solid materials used at the time.

“You have all this left-over energy, and when disposing of it, the end product is heat,” said Walz. “So I thought, why not first give the beam a bath?”

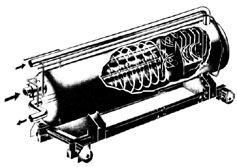

Walz's final design looks like a water heater on wheels. The 15-foot long device has a thin entry window at one end, into which the beam passes. Inside, water under high-pressure corkscrews around at high speed, as if circling a drain, bathing and cooling the internal components as well as absorbing the initial blast of electron energy as it enters. By the time the electron beam reaches the back of the device, it has lost enough energy to then pass into solid plates of copper, which finish the job.

This type of beam dump can circulate up to 500 gallons of water a minute. Once the water leaves the beam dump, it then passes through a series of heat exchangers to cool it down and into a surge tank that stores it to be recirculated later. This closed-loop system eliminates the radiation hazard produced as water is exposed to the electron beam.

Walz's beam dumps have operated at SLAC for 40 years. During that time, Walz developed a variety of simpler designs, such as solid blocks of tungsten, aluminum or copper, or hollow, water-cooled drums filled with tiny aluminum spheres. Many such beam dumps are used at SLAC to dissipate the energy of low-energy accelerator beams. But even now, as physicists and engineers prepare to build the International Linear Collider (ILC), the high-power beam dump of Walz's original design is proposed to catch the spent electron and positron beams. Only this time, the accelerator will pack even more of a punch at 10 to 20 times the power of SLAC’s original linac. The finished beam dump, which must be able to absorb the energy equivalent of thousands of pounds of explosives, will be the size of a small yacht.

—Brad Plummer

SLAC Today, July 17, 2006

Above image: Original engineering sketch of the high-power beam dump used to dissipate the energy of SLAC’s linac (Click on image for larger version.)

Addendum to "Electrons in Hot Water"

by Dieter Walz

On 7-12-06 I was interviewed by Brad Plummer on the subject of how to finally dispose of the "spent" electron beams after they have produced the sought after physics results. The resultant article seems to imply that I was the only inventor and designer of the large beam dump using water as the primary beam energy absorption medium. Quite to the contrary, there were other colleagues who made this program a success, and I am compelled to correct this inaccuracy. Edward Garwin and Joseph Jurow were co-inventors of the 2 MW beam dump concept. Other individuals also made essential contributions to this program—they are L. Lucas, E. Seppi, R. Vetterlein, J. Wagner, H. Weidner and, for more recent work, A. McFarlane. I apologize to my colleagues for the omission of credit that is due them.