Handy Links

SLAC News Center

SLAC Today

- Subscribe

- Archives: Feb 2006-May 20, 2011

- Archives: May 23, 2011 and later

- Submit Feedback or Story Ideas

- About SLAC Today

SLAC News

Lab News

- Interactions

- Lightsources.org

- ILC NewsLine

- Int'l Science Grid This Week

- Fermilab Today

- Berkeley Lab News

- @brookhaven TODAY

- DOE Pulse

- CERN Courier

- DESY inForm

- US / LHC

SLAC Links

- Emergency

- Safety

- Policy Repository

- Site Entry Form

- Site Maps

- M & O Review

- Computing Status & Calendar

- SLAC Colloquium

- SLACspeak

- SLACspace

- SLAC Logo

- Café Menu

- Flea Market

- Web E-mail

- Marguerite Shuttle

- Discount Commuter Passes

-

Award Reporting Form

- SPIRES

- SciDoc

- Activity Groups

- Library

Stanford

Around the Bay

X-Ray Diffraction and the Fight Against Heart Disease

Endovascular stents—tubes inserted into arteries to keep them from constricting—manufactured from superelastic Nitinol represent a major component in the fight against heart disease. However, understanding the stress and strain distributions in such stents, which lead to deformation and fracture, is essential for their prolonged safe use in human arteries.

Endovascular stents—tubes inserted into arteries to keep them from constricting—manufactured from superelastic Nitinol represent a major component in the fight against heart disease. However, understanding the stress and strain distributions in such stents, which lead to deformation and fracture, is essential for their prolonged safe use in human arteries.

Nitinol, an alloy of nickel-titanium, can "remember" a previous shape and can recover strains as high as 10% by deformation (whereas most other metals can recover only about 0.5%). Deformation mechanisms of Nitinol are more complex than the conventional modes of plastic deformation in traditional alloys, and, as a result, the mechanical behaviour of Nitinol under multiaxial conditions remains poorly understood.

Nevertheless, design of first-generation Nitinol stents using detailed finite-element analysis based on empirical modifications to the conventional theory of deformation has proved very successful for applications where predominant deformation is the "breathing mode" generated by the pulsatile differentials from the cardiac cycle. But recently, stents are prescribed for more and more applications in the peripheral arteries. The peripheral vessels undergo large amplitude multi-axial displacements. For example, the superficial femoral arterie (SFAs) is subjected to up to 60% rotation and about 20% contraction when the knee is bent from an extended position. Correspondingly, during a walking cycle, a stent deployed in the SFA not only undergoes displacements from pulsatile motion (about 40 million cycles annually) but also severe multiaxial deformation from bending, torsion, and axial motions (at a rate of about one million cycles annually). Not surprisingly, empirical design models fail to predict stresses on stents under these severe loading conditions and sometimes stents break. To better predict the mechanical behavior of superelastic Nitinol under these severe multi-axial deformations a much better understanding of the microscopic mechanism of deformation is necessary.

A complex material like Nitinol undergoes deformation at the microscopic scale through four distinct mechanisms (often called modes of microstrain). The first two mechanisms—elastic deformation (reversible deformation of atomic bonds) and plastic deformation (irreversible breakage of bonds in formation of dislocations and slip planes)—are common to all metals. The other two modes of microstrain, strain due to a phase transition and strain generation and accommodation through re-orientation of martensite twins, are more specific to Nitinol under large deformations and are very poorly understood.

X-ray diffraction is a very powerful technique for measuring microstrains not only because it is one of the few techniques that can distinguish among the four different modes of microstrain, but also because it is a non-contact probe with large penetration depth. This allows it to be easily incorporated into an in-situ measurement. Over the last two years we, in collaboration with Prof Rob Ritchie's group at Lawrence Berkeley Laboratory and Dr. Alan Pelton's research group at Nitinol Devices & Components/Johnson & Johnson (a stent manufacturer), have been using synchrotron based diffraction and microdiffraction at the Stanford Synchrotron Radiation Laboratory and the Advanced Light Source to probe the various modes of microstrain in mechanically simple and better defined and sometimes on more complex stent-like Nitinol objects.

Our investigation is far from complete, but our results indicate that the elastic mode of deformation in Nitinol is not dissimilar to elastic deformation of other metals. But the other three modes of microstrain are a lot more complex than earlier envisioned. The nucleation of martensite from austenite and re-orientation of martensite twins has significant barrier and this barrier has a strong and still poorly understood crystallographic anisotropy. The nucleation barrier anisotropy translates into a strong crystallographic texture dependent tension-torsion-compression anisotropy at large deformations and makes the prediction of the mechanical behavior under those conditions non-trivial.

—Apurva Mehta

SLAC Today, November 2, 2006

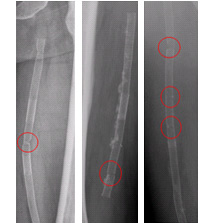

Above image: Three images of broken stents in the Superficial femoral artery, which runs down the leg. (Image courtesy of C. Bonsignore.)