Handy Links

SLAC News Center

SLAC Today

- Subscribe

- Archives: Feb 2006-May 20, 2011

- Archives: May 23, 2011 and later

- Submit Feedback or Story Ideas

- About SLAC Today

SLAC News

Lab News

- Interactions

- Lightsources.org

- ILC NewsLine

- Int'l Science Grid This Week

- Fermilab Today

- Berkeley Lab News

- @brookhaven TODAY

- DOE Pulse

- CERN Courier

- DESY inForm

- US / LHC

SLAC Links

- Emergency

- Safety

- Policy Repository

- Site Entry Form

- Site Maps

- M & O Review

- Computing Status & Calendar

- SLAC Colloquium

- SLACspeak

- SLACspace

- SLAC Logo

- Café Menu

- Flea Market

- Web E-mail

- Marguerite Shuttle

- Discount Commuter Passes

-

Award Reporting Form

- SPIRES

- SciDoc

- Activity Groups

- Library

Stanford

Around the Bay

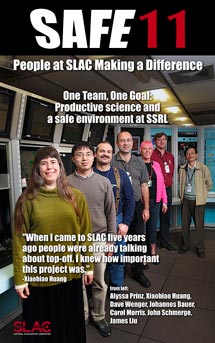

SAFE2011: SLAC Team Ensures Safety of SPEAR3 Upgrade

Ensuring the safety of Stanford Synchrotron Radiation Lightsource users and staff has been a guiding principle in the ongoing effort to bring the SPEAR3 accelerator up to its design capacity of 500 milliamperes of current. This principle has never been more evident than during the shift to top-off injection last year. This operating mode permits the addition of electrons to the SPEAR3 storage ring while the X-ray beamline injection stoppers remain open—a radical change from past procedure.

"Before top-off, the injection stoppers had to be inserted for all injections," said James Liu, a radiation physicist with SLAC's Radiation Protection Department, which is charged with providing support and oversight for the radiological safety of accelerators, beamlines and experiments. The electrons circulating around the SPEAR3 storage ring, emitting the X-rays needed by SSRL users, require a periodic boost in the form of more electrons, which are "injected" into the ring. More-frequent injections support a higher beam current—more X-rays for user experiments.

As Liu explained, during injections, each of the beamlines that channel X-rays to users would close a pair of injection stoppers to prevent electrons in the storage ring from entering. But the stoppers prevented the X-rays from entering the beamlines as well, requiring a pause in user experiments. Fifteen to 20 minutes of injection every eight hours for low current operation was an acceptable interruption. "SPEAR2 and SPEAR3 ran like that for 20 years," Liu said.

However, running in this mode meant operating at a lower current and delivering less beam to users when compared to the facility's potential. Yet increasing the SPEAR3 current would result in faster beam decay and require more frequent injections. Moreover, interrupting the X-ray beams during injection periods causes thermal distortions in the X-ray optics that contribute to beam instability. Thus, to reach its full design capability and maintain stable beams, the SPEAR3 storage ring required a new mode of operation during which beamlines remained open during injection.

"Keeping the stoppers open is better for operation, for experiments, and also for the beamlines," Liu acknowledged, but from the point of view of radiation safety the picture was more challenging. "There was a possibility the injection beam could accidentally channel into a beamline. And in the worst-case scenario, it could go to the floor,"—a remote possibility, true, but one which could pose a significant radiation hazard.

Radiation Protection team lead Johannes Bauer and colleague Alyssa Prinz worked with the SPEAR3 accelerator group led by John Schmerge to design a radiation safety system that could prevent such a mishap. But while electrons themselves are miniscule, the task of evaluating and guarding against all the ways they might misbehave was not.

"You have to start with, 'what are all the possible trajectories electrons could be on?'" said James Safranek, head of the SPEAR3 accelerator physics group. "Usually you operate with some reasonable set of constraints, so you come up with a fairly reasonable set of trajectories." But in this case, Safranek explained, they could make no assumptions, because for safety purposes "we had to consider any wildly crazy error that might happen and include that in the tracking study."

"The safety system requirements clearly depended on the simulations from the SPEAR3 accelerator physics group," Liu said.

Enter SPEAR3 accelerator physicist Xiaobiao Huang.

"When I came to SLAC five years ago people were already talking about top-off," Huang said. "I knew how important this project was."

According to Schmerge, "We assigned [the project] to Xiaobiao and he did a tremendous job. His attention to detail and quick delivery of a solid proof of safety was critical for the timely implementation of top-off operation." Huang stepped in again to improve control over the trajectory of the injected beam when measurements showed too much of the beam was getting "lost" in the insertion device vacuum chambers, where the namesake radiation for which a synchrotron is known is actually generated.

Verifying the work required extensive testing. Bauer and his people, together with Radiation Protection Department technicians led by Carol Morris, conducted radiation surveys during top-off testing at each beamline. The surveys took place during evening shifts to minimize disruption and required clearing all personnel off the floor to minimize potential exposure. The entire process took months.

"The first time we did this we wrote a comprehensive procedure to clear the floor and make sure that everything was ready and everybody knew what to do," Bauer said. Should the tests indicate that radiation shielding required adjustment, Dave Wenger, of SSRL Beamline Development and Support, was in charge of making shielding modifications.

"He was the guy who—push come to shove—if there was a leak, he fixed it," said Tom Rabedeau, head of Beamline Development and Support. "Dave was instrumental in getting the lead where it belonged."

Now SPEAR3 reliably delivers 300mA to 13 beamlines equipped to handle the extra X-rays. Not only that, but SPEAR3 got an improved injector, the beamlines got better shielding, and a new type of radiation detector was added to each beamline for top-off operation.

But looking at individual gains is missing the point, Rabedeau said. "The accelerator group, the SSRL team members and the Radiation Protection team members all had the same goal—more productive science and safe environment for our users and a facility that meets its design goals."

—Lori Ann White

SLAC Today, February 17, 2011