Handy Links

SLAC News Center

SLAC Today

- Subscribe

- Archives: Feb 2006-May 20, 2011

- Archives: May 23, 2011 and later

- Submit Feedback or Story Ideas

- About SLAC Today

SLAC News

Lab News

- Interactions

- Lightsources.org

- ILC NewsLine

- Int'l Science Grid This Week

- Fermilab Today

- Berkeley Lab News

- @brookhaven TODAY

- DOE Pulse

- CERN Courier

- DESY inForm

- US / LHC

SLAC Links

- Emergency

- Safety

- Policy Repository

- Site Entry Form

- Site Maps

- M & O Review

- Computing Status & Calendar

- SLAC Colloquium

- SLACspeak

- SLACspace

- SLAC Logo

- Café Menu

- Flea Market

- Web E-mail

- Marguerite Shuttle

- Discount Commuter Passes

-

Award Reporting Form

- SPIRES

- SciDoc

- Activity Groups

- Library

Stanford

Around the Bay

Frequent Injection Mode Boosts Resolution for SSRL Users

After months of planning and testing, the Stanford Synchrotron Radiation Lightsource began its first user run with the SPEAR3 storage ring operating in frequent injection mode yesterday. This is the most recent in a series of steps toward operating at its full design current of 500 milliamperes, which aims to provide faster and higher resolution data collection for SSRL users.

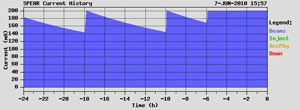

SSRL began running in what's called top-off mode last year, with the last few beamlines approved for top-off earlier this year. Photon beamlines remained open while electrons were injected into the SPEAR3 storage ring three times a day to replenish the 200-mA current. Still operating in top-off mode, these injections now happen once every 10 minutes, or 144 times a day.

"The number one advantage for operating this way is power constancy," said Tom Rabedeau, who works on beamline developments at SSRL. The frequent injections allow the current to remain relatively stable, dropping only about 1.5 mA before more electrons are added. Since the optics used to focus and guide the beams can experience thermal distortion under larger current fluctuations, they perform better under the nearly constant power load provided by the smaller, more frequent injections.

Replacing such a small amount of current also allows quicker fills. Each injection takes only a few seconds to become integrated into the circulating beam and does not interrupt user data collection. Before frequent fills, the beam's intensity dropped significantly between injections and users had to time their data collection carefully within each cycle. Now that the intensity remains stable, they can collect data continuously and use their beam time more efficiently.

"We can also really improve our image quality," said SSRL staff scientist Joy Andrews Hayter, who uses SSRL's X-ray beams to image biological, environmental and energy-related materials with nanometer resolution. Getting good images of the materials requires subtracting the picture of the beam from her data. The stable beam intensity keeps the reference picture of the beam consistent, making it easier to remove from the images of her sample materials.

The successful operation of frequent injection mode is a necessary step toward operating at full design current—a journey that has been years in the making and meticulously planned. "This has been a story of solving technical problems, and ensuring that safety, machine reliability and user data will not be affected adversely," Rabedeau said.

"The fundamental challenge was that the injector wasn't designed to turn on and off frequently," said Accelerator Directorate physicist John Schmerge. Optimizing the injector for frequent fills included adding 15 beam position monitors in the transport lines needed to optimize the electron trajectory, upgrading the pulsed magnets that kick the beam into and out of the booster synchrotron, rebuilding the booster-to-SPEAR3 transport line to improve beam capture efficiency and adding many feedback systems to keep the beam parameters nearly constant. The team also had to develop the algorithm and necessary controls to turn the injector on and off automatically every ten minutes so as not to damage the accelerator or increase the radiation levels.

Radiation safety was a primary focus during the project. SSRL's user beamlines do not shut down during the injections, which would pose a radiation hazard if any electrons could escape and reach the user areas. SSRL staff and SLAC radiation physicists worked together to design a system that would prevent any such occurrence. Then they ran tests with various beam conditions and found the radiation levels on the floor to be very low, within the limits set in the design.

"SSRL set the right tone for safety," said Radiation Safety Officer Sayed Rokni. "They were proactive, and the project was done in an exemplary manner from planning to execution."

Rokni and his staff will continue to monitor the radiation levels within SSRL as the current climbs higher, although their rigorous tests are complete. The SSRL team is likely to test currents as high as 300 to 350 mA during this run to get a sense of the quality of data and verify that radiation safety is preserved.

As the operating current increases, it will decay more quickly and require more frequent injections to maintain identical current stability. To this end, the accelerator team is developing a trickle-charge injection mode, which injects a single bunch of electrons every 1-2 minutes instead of 40 bunches every 10 minutes, resulting in exceptional stability. Ultimately, users will get more data per unit time or be able to improve the spatial resolution in their research.

"The improvements that will be put in place for even more frequent injections are the beginning of a more comprehensive upgrade program that has been proposed to [the Department of Energy], and that will keep SPEAR3 at the state-of-the-art into the next decade," said SSRL Acting Director Piero Pianetta.

—Lauren Rugani

SLAC Today, June 8, 2010