Handy Links

SLAC News Center

SLAC Today

- Subscribe

- Archives: Feb 2006-May 20, 2011

- Archives: May 23, 2011 and later

- Submit Feedback or Story Ideas

- About SLAC Today

SLAC News

Lab News

- Interactions

- Lightsources.org

- ILC NewsLine

- Int'l Science Grid This Week

- Fermilab Today

- Berkeley Lab News

- @brookhaven TODAY

- DOE Pulse

- CERN Courier

- DESY inForm

- US / LHC

SLAC Links

- Emergency

- Safety

- Policy Repository

- Site Entry Form

- Site Maps

- M & O Review

- Computing Status & Calendar

- SLAC Colloquium

- SLACspeak

- SLACspace

- SLAC Logo

- Café Menu

- Flea Market

- Web E-mail

- Marguerite Shuttle

- Discount Commuter Passes

-

Award Reporting Form

- SPIRES

- SciDoc

- Activity Groups

- Library

Stanford

Around the Bay

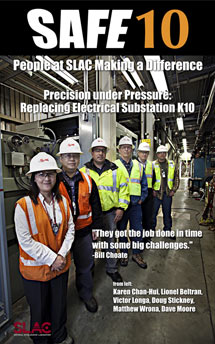

SAFE2010: Electrical Substation K10

It was a deceptively quick and quiet turnover in the Klystron Gallery during winter break. With the replacement of electrical Substation K10, SLAC kicked off 2010 with an exemplary demonstration of how meticulous planning can lead to safe execution.

"It's one of the most critical areas of the lab," said Bill Choate, the electrical group leader from the Facility Division Operations Group. Substation K10 was a leftover relic from the original lab construction in the 1960s, and with its 40-year-old infrastructure, an upgrade was due.

This substation is the main power source for klystrons in Sectors 19 and 20, powering the linac and serving the Linac Coherent Light Source.

Swapping out the substation would be tricky, because the entire klystron gallery had to be completely powered down. Electrical lines are routed through areas that workers needed to access, creating possible safety hazards. Cutting off the electrical supply carries its own risks: around fifteen years ago, water pipes froze when the gallery was without power during a bad cold snap. Were that to happen today, it could cost as much as one million dollars to repair the piping system.

Upping the stakes, the team needed two weeks of power outage to perform electrical work, the longest period of time the gallery would ever go without power. Plans for the December 2009 shutdown began in July of 2008, producing a three-hundred plus page document that detailed the steps and safety precautions. The K10 team was careful to warn all users about the klystron power-free time period, during winter break in late December 2009, through e-mail, memos, meetings and discussions with building managers and linac stakeholders.

It took three full days to set up temporary generators—18 in total—and power down the klystron gallery, and another three days bring it back to life. The generators provided electricity for lighting and other critical equipment during the interim.

All the while, the crew carefully monitored the air temperature, ensuring it did not slip below 32 degrees Fahrenheit and freeze the pipes. Heaters were on stand-by in case the temperature dropped. Throw in the task of generator refueling, a two-week time constraint and the team had quite a logistical puzzle.

The challenge was met with careful planning, clean execution and hard work over the holiday break.

"The team worked very hard on it," Karen Chan-Hui said. Chan-Hui was the Project Manager overseeing the substation replacement. "They were working twelve hour days for two weeks during the down time. Everyone else was home for Christmas."

At SLAC were the project team, staff from the Facilities and ES&H Divisions and Scott Wenholz from the Department of Energy site office. Wenholz was on site to provide Federal oversight. Everyone involved called the project an enormous success-no accident, injuries, and finished on schedule. The team credits their careful planning and concentration under pressure.

"They got the job done in time with some pretty big challenges," Choate said.

Thanks go to several engineers under the leadership of Javier Sevilla, and service technicians under the leadership of Bill Choate, Ray Radau, Ken Rubino and Marty O'Donoghue who supported this important project, as well as Lori Shewchuk, who helped the project manager at the critical phases of the project.

óJulie Karceski

SLAC Today, March 4, 2010