Handy Links

SLAC News Center

SLAC Today

- Subscribe

- Archives: Feb 2006-May 20, 2011

- Archives: May 23, 2011 and later

- Submit Feedback or Story Ideas

- About SLAC Today

SLAC News

Lab News

- Interactions

- Lightsources.org

- ILC NewsLine

- Int'l Science Grid This Week

- Fermilab Today

- Berkeley Lab News

- @brookhaven TODAY

- DOE Pulse

- CERN Courier

- DESY inForm

- US / LHC

SLAC Links

- Emergency

- Safety

- Policy Repository

- Site Entry Form

- Site Maps

- M & O Review

- Computing Status & Calendar

- SLAC Colloquium

- SLACspeak

- SLACspace

- SLAC Logo

- Café Menu

- Flea Market

- Web E-mail

- Marguerite Shuttle

- Discount Commuter Passes

-

Award Reporting Form

- SPIRES

- SciDoc

- Activity Groups

- Library

Stanford

Around the Bay

People: The Light Machine Shop Does Some Heavy Lifting

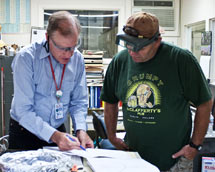

It's pushing 3 p.m.—time to clock out in less than an hour—and design engineer Brian Duda appears in the machine shop office with two foil-wrapped parts that need tweaking. He bends over them in consultation with floor supervisor Craig Jordan, who's holding down the fort while the shop's manager, Denise Larsen, is out. The parts are needed for fabrication of the germanium crystals that form the heart of the Super Cryogenic Dark Matter Search detector. It's a rush job. They're always rush jobs.

"He's a popular guy," Duda says of Jordan, who is studying CAD drawings of the parts.

"A German guy on the [Linac Coherent Light Source] tried to tip me," Jordan adds. "I had to tell him, 'I can't take money!' But he did ask me out for a beer, later."

The two finish their consultation and Duda turns to leave. "Really," he says, tone serious, "these are great guys to work with and very competent."

Jordan shrugs off Duda's compliment. "This one will be pretty easy," he says, pointing to a thick, sturdy aluminum ring. "He just needs a little shaved off the top."

How much is a little?

".025 of an inch," Jordan says. "About eight human hairs' worth."

Such precision is all in a day's work for the fifteen machinists in the Mechanical Fabrication Department's Light Machine Shop. They specialize in turning rods or sheets or blocks of aluminum, copper, brass and bronze, stainless steel and tungsten into custom parts for the myriad experiments that take place at SLAC facilities. According to Jordan, they work in close collaboration with their customers, whether SLAC employees or users who need a part for an experiment. "It's a team effort, for sure," Jordan says.

Paul Tomasi is building a beamline shutter for the LCLS Soft X-Ray instrument. He fits the shutter parts together, but they currently lack… coherence.

"Next this will go to our crackerjack welders," says Tomasi. Other parts might require plating. Or they might need to be joined by brazing—and from there either go directly to the users or come back to the shop for finishing. All well-worn steps in the process of making a custom part. But being a team player can have its challenges, as Tomasi explains.

"Sometimes we'll work off prints, sometimes we'll work off a cocktail napkin some physicist brings in." Oddly, he sounds admiring. "There are some really smart people here."

The varying requirements of all the really smart people who stop by keep the machinists on their toes. A full complement of computerized and manual lathes and mills, along with the EDMs, or electric discharge machines, enable the machining of parts from stock that might weigh more than ton, or might be the thickness of a sheet of paper.

"My work involves rigging and cranes," says Clifton Caston, who, along with Athikorn (Ben) Pienpicharn, usually handles the big stuff. Or the stock might be brought in by forklift, often driven by the shop's own Joe Diaz, because, says Caston, "Joe's an artist with a forklift." However the stock is brought in, once it's in the shop Caston is responsible for ensuring that it's safely mounted on the shop's large-capacity mill. "This will handle stock up to 100 inches in x [axis] and 60 inches in y [axis]," Caston says. Plenty big enough to machine a one-ton piece of metal to use in certification classes for crane operators.

The machine shop can handle fine detail just as handily. One of the EDM machine operators, Peter Franco, is already known for the Snoopy cutouts he made for a SLAC Kid's Day. "People still ask me for them," Franco says.

Some may consider the Snoopies to be cute tsotchkes, but they're also evidence of Franco's skill level, a requirement for making the the custom parts that make SLAC science possible. He shares that level of skill with the rest of the machinists in SLAC's Light Machine Shop. It's just one of the attributes that make them good team members.

"When it comes to the precision work we do you've really got to know your stuff," Jordan says.

—Lori Ann White

SLAC Today, September 28, 2010