Handy Links

SLAC News Center

SLAC Today

- Subscribe

- Archives: Feb 2006-May 20, 2011

- Archives: May 23, 2011 and later

- Submit Feedback or Story Ideas

- About SLAC Today

SLAC News

Lab News

- Interactions

- Lightsources.org

- ILC NewsLine

- Int'l Science Grid This Week

- Fermilab Today

- Berkeley Lab News

- @brookhaven TODAY

- DOE Pulse

- CERN Courier

- DESY inForm

- US / LHC

SLAC Links

- Emergency

- Safety

- Policy Repository

- Site Entry Form

- Site Maps

- M & O Review

- Computing Status & Calendar

- SLAC Colloquium

- SLACspeak

- SLACspace

- SLAC Logo

- Café Menu

- Flea Market

- Web E-mail

- Marguerite Shuttle

- Discount Commuter Passes

-

Award Reporting Form

- SPIRES

- SciDoc

- Activity Groups

- Library

Stanford

Around the Bay

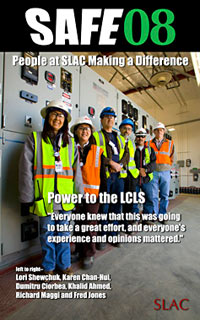

SAFE '08 Success Story: Power to the LCLS

Working with over 12,000 volts of electricity—especially in the limited space of a manhole—is by no means a simple or inherently safe task. But for a recent Linac Coherent Light Source (LCLS) project, which combined the talents of Facilities Project Managers, University Technical Representatives, Engineering and Operations Electricians, the Electrical Safety Officer Department, the Mechanics Group and two groups of subcontractors, the melding of experience and detailed planning ensured the project's safe and successful completion.

Working with over 12,000 volts of electricity—especially in the limited space of a manhole—is by no means a simple or inherently safe task. But for a recent Linac Coherent Light Source (LCLS) project, which combined the talents of Facilities Project Managers, University Technical Representatives, Engineering and Operations Electricians, the Electrical Safety Officer Department, the Mechanics Group and two groups of subcontractors, the melding of experience and detailed planning ensured the project's safe and successful completion.

The work was performed to feed power to a new substation for the LCLS project. Bringing power to the substation required cable splicing inside manholes, switching lines and conducting thorough inspections and tests along the way.

"With qualified people backing you and proper planning, a lot can be done," said LCLS Facilities Electrical Engineer and Project Manager Lori Shewchuk. "Our objective is for everyone to go home safe."

Before any electric work began, the team put tremendous effort into discussing the project's procedures and developing a work plan a week before it took place.

"Everyone knew that this was going to take a great effort, and everyone's experience and opinions mattered," Shewchuk explained. "To make it all happen safely, and correctly, we needed to listen to each other."

The work plan, which used the Integrated Safety and Environmental Management System (ISEMS) process, described all steps to be performed. This plan was developed with input from all involved in the work and was reviewed by the Stanford Site Office (SSO). This planning process helped ensure that everyone involved knew their roles and responsibilities, the scope of work, the hazards and controls and what to do if abnormal or upset conditions existed.

The work plan, which used the Integrated Safety and Environmental Management System (ISEMS) process, described all steps to be performed. This plan was developed with input from all involved in the work and was reviewed by the Stanford Site Office (SSO). This planning process helped ensure that everyone involved knew their roles and responsibilities, the scope of work, the hazards and controls and what to do if abnormal or upset conditions existed.

"They really took their work planning and control to a whole new level," Department of Energy Environment, Health and Safety and Facility Operations Team Leader Tom Rizzi said. "It was very well done."

The project did come to a halt for a few weeks when SLAC's high voltage electricians observed excessively loud buzzing coming from a control power transformer inside the substation. Because electricians suspected it was coming from the switchgear, the equipment that houses circuit breakers, they immediately suspended all work until the source—and thus the level of hazard—could be determined.

As soon as the switchgear manufacturer’s technician arrived to participate in troubleshooting, the problem was fixed on the spot. The control power transformer, a large drawer-like component that is slid into place, had its connection clips spaced too far apart. Once the clips were pinched down, the problem was solved and the feeder could be energized.

As soon as the switchgear manufacturer’s technician arrived to participate in troubleshooting, the problem was fixed on the spot. The control power transformer, a large drawer-like component that is slid into place, had its connection clips spaced too far apart. Once the clips were pinched down, the problem was solved and the feeder could be energized.

Compiling so many groups of people and including everyone in, from the beginning of planning, proved to be the key feature of the project's safety success. Everybody was on the same page and understood their roles and responsibilities.

"We really pulled together a lot of resources to complete this activity," Shewchuk said. "We appreciate everyone's cooperation. Everybody’s efforts were so valuable."

—Matt Cunningham, SLAC Today, April 30, 2008

Top image, from left to right: Facilities Department Operations Electricians Lori Shewchuk, Karen Chan-Hui, Dumitru Ciorbea, Khalid Ahmed, Richard Maggi and Fred Jones. Not pictured are Charles McKenzie, Jose Regalado, John Blomdal, Mike Cook, Eddie Viray, Gerardo Lorenzo and James Kang.

Center image: Twelve kilovolt lines in Manhole #49. (Click on image for larger version.)

Bottom image: Electricians in breaker substation wearing electric arc flash protective equipment. (Click on image for larger version.)