Handy Links

SLAC News Center

SLAC Today

- Subscribe

- Archives: Feb 2006-May 20, 2011

- Archives: May 23, 2011 and later

- Submit Feedback or Story Ideas

- About SLAC Today

SLAC News

Lab News

- Interactions

- Lightsources.org

- ILC NewsLine

- Int'l Science Grid This Week

- Fermilab Today

- Berkeley Lab News

- @brookhaven TODAY

- DOE Pulse

- CERN Courier

- DESY inForm

- US / LHC

SLAC Links

- Emergency

- Safety

- Policy Repository

- Site Entry Form

- Site Maps

- M & O Review

- Computing Status & Calendar

- SLAC Colloquium

- SLACspeak

- SLACspace

- SLAC Logo

- Café Menu

- Flea Market

- Web E-mail

- Marguerite Shuttle

- Discount Commuter Passes

-

Award Reporting Form

- SPIRES

- SciDoc

- Activity Groups

- Library

Stanford

Around the Bay

3-D Printer Puts Detector at Your Fingertips

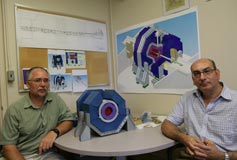

Blueprints decorate the desk top and design printouts cover the walls of Marco Oriunno's office. They all display plans for a potential particle detector for the International Linear Collider. But to show off the detector, Oriunno goes straight for a pile of colorful plastic. He and Norman Graf stack the pieces together like oversized Legos and voilà! A 3-D version of the detector that can be displayed to scientists, engineers and other project members to help them better understand the massive detector they are trying to build.

Graf and Oriunno are planning the detector as members of the international Silicon Detector Design Collaboration. While design software allows Oriunni and Graf to map out the detector before it is built, Graf says the 3-D model reveals its physical structure in a way that can't be achieved with software images alone. "It's another learning tool. To have both the fully developed design in CAD [computer aided design] and the 3-D model makes a good convergence."

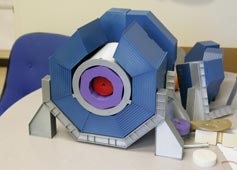

Eight baseball-sized blue trapezoids (painted by Graf and Oriunno) represent a section of the detector used for muon identification, the barrel magnetic flux return. In the real detector, these trapezoids will weigh 400 metric tons each. A magnetic coil (silver) encloses further, central detection equipment, including the 12-sided hadronic calorimeter (purple), the electromagnetic calorimeter (not visible) and the tracking detectors (red).

The model answers questions for engineers about how to assemble the real thing. Graf and Oriunno explain that their detector could possibly share the beam with a second, so they need to make it mobile. The model may help engineers find a way of moving the detector without taking it apart.

The 3-D printer cost SLAC nearly $30,000, but it seems to be earning its keep quickly. For a machinist to create the model by hand would cost at least a few thousand dollars, Oriunno says. The printer produced the 3-D model for just a few hundred dollars. Instead of paying a machinist for every hour it takes to produce the model, the printer only requires manpower for setup and entry of commands. Then the machine runs by itself day and night, taking about one month to produce all the pieces for the detector model.

Graf and Oriunno say the printer is useful for generating rapid prototypes, and making new models if plans change or errors are detected. The two scientists say they will continue to use the printer to make 3-D models of smaller parts of the detector. Depending on the size and number of jobs in the queue, the printer runs non-stop for months, or remains available for immediate use.

—Calla Cofield

SLAC Today, November 6, 2008