Handy Links

SLAC News Center

SLAC Today

- Subscribe

- Archives: Feb 2006-May 20, 2011

- Archives: May 23, 2011 and later

- Submit Feedback or Story Ideas

- About SLAC Today

SLAC News

Lab News

- Interactions

- Lightsources.org

- ILC NewsLine

- Int'l Science Grid This Week

- Fermilab Today

- Berkeley Lab News

- @brookhaven TODAY

- DOE Pulse

- CERN Courier

- DESY inForm

- US / LHC

SLAC Links

- Emergency

- Safety

- Policy Repository

- Site Entry Form

- Site Maps

- M & O Review

- Computing Status & Calendar

- SLAC Colloquium

- SLACspeak

- SLACspace

- SLAC Logo

- Café Menu

- Flea Market

- Web E-mail

- Marguerite Shuttle

- Discount Commuter Passes

-

Award Reporting Form

- SPIRES

- SciDoc

- Activity Groups

- Library

Stanford

Around the Bay

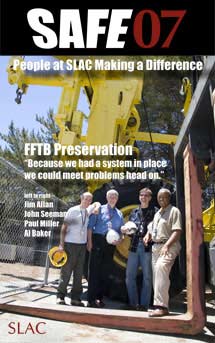

SAFE '07 Success Story: FFTB Preservation Project

SLAC's evolving research yard is a bustling place. Here, just beyond the beam switch yard, End Station A runs test beams, End Station B does research and development work for the International Linear Collider and advanced accelerators, experimental shops hum with activity, and other associated facilities support the lab's research programs.

SLAC's evolving research yard is a bustling place. Here, just beyond the beam switch yard, End Station A runs test beams, End Station B does research and development work for the International Linear Collider and advanced accelerators, experimental shops hum with activity, and other associated facilities support the lab's research programs.

Last year, in the midst of all this activity, a team of SLAC employees, users and contractors completed the very complex Final Focus Test Beam (FFTB) Preservation Project, removing the installation to make way for the Linac Coherent Light Source (LCLS) Beam Transport Hall, without a single injury.

"We had three tasks: first, we had to make the FFTB safe for the main removal of the facility, then we had to complete the actual removal, and finally we had to turn the area over to the conventional facilities group for construction," said Richard M. Boyce, Project Manager for the preservation project. "We accomplished all three of these very complex phases very safely through teamwork."

Just days after the last experimenter left the building, the FFTB preservation team began its work, taking a fully operational beamline, powering it down, and securing the facility for component removal with an emphasis on preserving as many components as possible. Carefully considering safety issues, crews worked systematically to identify reusable components before disconnecting the FFTB's electrical, water and protection systems.

"The effort was a fine example of coordination within the lab and with the contractors," said LCLS Senior Field Construction Manager Bob Law. "Many hazardous activities were performed safely and in an exemplary manner."

The process required detailed attention to electrical safety, which included powering down electrical sources, verifying the power down, determining which cables connect to which other cables, ensuring that workers wear appropriate Personal Protective Equipment, and finally severing cables for removal. The process also demanded many hours of radiological surveying and meticulous attention to radiation safety to ensure proper identification, labeling and storage of radioactive materials.

Samples of the concrete and soil beneath the FFTB were also tested for radioactivity. All activated material was excavated and packaged for proper storage and disposal.

"The project's many mechanics and technicians made this a success by applying teamwork and dedication and ensuring a safe successful project down to the last bag of soil removed," said Jim Allan, Radiation Protection Field Operations Group Leader.

The FFTB Preservation Project also included the removal of lead components (paying special attention to lead dust on the floor of the building), the protection of delicate instruments, and the removal of very heavy and unwieldy items using proper hoisting and rigging techniques.

"When the contractor rolled in, the whole FFTB was dark and cold," said John Seeman, Head of the Accelerator Systems Division. "We successfully made the area safe for the contractor."

In addition to the very complex nature of the project, the FFTB preservation team also completed their work in a very small physical area. Sandwiched between End Station A and End Station B, the FFTB was very near still-operational beamlines. This left little space for the removal project, and required crews to work in close proximity.

To mitigate the project's many hazards, the safety team planned, scheduled and choreographed the project months in advance. Project managers began meeting six months before the start of demolition to determine in what order their tasks should be done, how long each task would take, and how each task might affect the others.

After the entire project was carefully scripted and scheduled, construction began, with as many as 20 crews doing work in a single day. All those working on a given day were required to attend a morning safety meeting. These meetings involved a review of the day's schedule, taking care to raise any previously unforeseen problems. The meetings also addressed evacuation routes, current hazards, and possible conflicts between concurrent jobs.

"Heavy emphasis was placed on following all safety and line management requirements," said Area Manager Al Baker. "This made it possible for us to complete a very intensive project in a very small area, and to do it safely."

Safety officers completed several safety walk-throughs each day, actively looking for areas and activities that could be made safer; in addition, someone was always available on site to answer any questions that might come up.

"Being ready to deal with any problem that came up helped us prevent bigger problems," said Paul Miller, Accelerator Systems Division Safety Officer. "Because we had a system in place, we could meet problems head on."

—Kelen Tuttle, SLAC Today, July 24, 2007