Handy Links

SLAC News Center

SLAC Today

- Subscribe

- Archives: Feb 2006-May 20, 2011

- Archives: May 23, 2011 and later

- Submit Feedback or Story Ideas

- About SLAC Today

SLAC News

Lab News

- Interactions

- Lightsources.org

- ILC NewsLine

- Int'l Science Grid This Week

- Fermilab Today

- Berkeley Lab News

- @brookhaven TODAY

- DOE Pulse

- CERN Courier

- DESY inForm

- US / LHC

SLAC Links

- Emergency

- Safety

- Policy Repository

- Site Entry Form

- Site Maps

- M & O Review

- Computing Status & Calendar

- SLAC Colloquium

- SLACspeak

- SLACspace

- SLAC Logo

- Café Menu

- Flea Market

- Web E-mail

- Marguerite Shuttle

- Discount Commuter Passes

-

Award Reporting Form

- SPIRES

- SciDoc

- Activity Groups

- Library

Stanford

Around the Bay

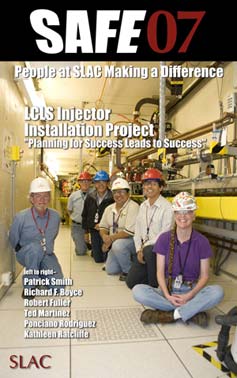

The LCLS Injector Installation: Planning for Success Leads to Success

When it comes to ensuring the safety and success of complex projects such as the Linac Coherent Light Source (LCLS) injector installation, thorough planning before the project even starts can make all the difference. This month,

SAFE07 focuses on how exceptional preplanning and communication have made the LCLS injector project a benchmark of safety success at SLAC.

When it comes to ensuring the safety and success of complex projects such as the Linac Coherent Light Source (LCLS) injector installation, thorough planning before the project even starts can make all the difference. This month,

SAFE07 focuses on how exceptional preplanning and communication have made the LCLS injector project a benchmark of safety success at SLAC.

The LCLS injector installation at Sector 20 was by any measure a complicated undertaking. To begin with, the original above-ground structure had to be removed, and a new building erected to house the LCLS drive laser. Thirty feet below, an existing vault required considerable reworking to accommodate the injector gun and hardware.

Led by project manager Bob Law, this initial phase of the injector installation set the stage for the successes to come. By the time the injector facility was ready for installation to begin, planning had long been underway to orchestrate the myriad overlapping tasks that would follow. Beginning in October of 2006, contractors from a variety of trades descended by turns below ground into the "cozy" injector vault to install support stands, magnets, injector pipe, radiofrequency gun, cables, cooling water systems and controls, to name only a few. Choreographing this ballet to accomplish the task safely and efficiently fell to installation manager Kathleen Ratcliffe, who attributes the success of the project to an extraordinarily efficient work planning and communication processes.

"It's all about having a written schedule and ensuring that everyone follows that schedule, so you know who's doing what, and when," said Ratcliffe.

The vault itself is not exactly a spacious setting, and the trickiest phase of the installation proved to be scheduling the many tasks in such a way as to keep working conditions as safe and as uncramped as possible.

The project capitalized on the expertise of SLAC workers and private contractors alike, and creating a common safety culture among those groups paid dividends for everyone. Personal Protective Equipment (PPE)—such as hard hats, safety glasses, steel-toe boots, etc.—is common in the construction industry and at SLAC, and the injector installation held to very strict standards of protection for all workers involved. The unique environment of the vault required continual evaluation of PPE requirements, which made effective communication from top to bottom essential.

According to LCLS Safety Coordinator Michael Scharfenstein, the overall success of the project stems from the consensus regarding safety between line managers Ratcliffe and Karen Fant, manager of the Mechanical Fabrication Department (MFD). Their mutual buy-in, he says, made safe work performance a condition of work.

"The key was the preplanning among the project managers, consensus around work planning processes and PPE requirements, and then communicating that to the workers," said Scharfenstein. "It was a large coordination effort. A lot was done early, and a lot was done on a daily basis. When we came to a roadblock, we had a way to resolve it."

The many groups involved convened each morning in "tailgate" meetings to evaluate the upcoming day's work. Such meetings enable evaluation of logistics and safety controls according to SLAC's Integrated Safety and Environmental Management System (ISEMS). During the work day, Scharfenstein conducted walk-throughs to provide encouragement and ongoing evaluation to help fine-tune the process. Scharfenstein says the Department of Energy SLAC Site Office and MFD Safety Coordinator Karen Holtemann both proved to be a tremendous help with the continuing evaluations, all of which translated into feedback to be communicated at the next day's tailgate meetings.

By April of this year, installation was complete—safely and on time—and commissioning of the injector was well underway. The first electron beam was observed on April 5, and was taken all the way through the LCLS injector and into the linac on April 14. Much of this early success was due to the coordination of the installation groups with the drive-laser and radio frequency (RF) groups, which safely commissioned the laser and RF systems during off-hours in order to better share the small injector vault space. By the end of a five-month long, first-phase commissioning effort, the electron beam from the new RF-gun was performing at or near its design specifications and was transported through the full linac at 14 GeV, according to Accelerator Physics Team Leader Paul Emma.

"This level of success would not have been possible without careful planning and the daily, tireless efforts of each individual involved with the design, installation and commissioning tasks," said Emma.

The work planning process used for the LCLS injector installation project is the result of many years' refinement of similar processes used during other Department of Energy Office of Science projects. Scharfenstein says that the successes and challenges met during the LCLS project will further that refinement, which will benefit future projects.

"When everyone understands what safety means, and everyone has a role, it creates a safer environment in general," Scharfenstein says. "It's all about work planning."

—Brad Plummer, SLAC Today, September 27, 2007