Handy Links

SLAC News Center

SLAC Today

- Subscribe

- Archives: Feb 2006-May 20, 2011

- Archives: May 23, 2011 and later

- Submit Feedback or Story Ideas

- About SLAC Today

SLAC News

Lab News

- Interactions

- Lightsources.org

- ILC NewsLine

- Int'l Science Grid This Week

- Fermilab Today

- Berkeley Lab News

- @brookhaven TODAY

- DOE Pulse

- CERN Courier

- DESY inForm

- US / LHC

SLAC Links

- Emergency

- Safety

- Policy Repository

- Site Entry Form

- Site Maps

- M & O Review

- Computing Status & Calendar

- SLAC Colloquium

- SLACspeak

- SLACspace

- SLAC Logo

- Café Menu

- Flea Market

- Web E-mail

- Marguerite Shuttle

- Discount Commuter Passes

-

Award Reporting Form

- SPIRES

- SciDoc

- Activity Groups

- Library

Stanford

Around the Bay

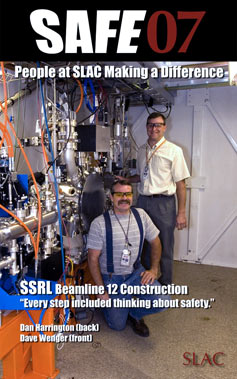

SAFE '07 Success Story: Beamline 12

Last March, a new beam line opened at the Stanford Synchrotron Radiation Laboratory (SSRL), thanks to three years of work by the Beam Line Development Group and about 50 designers, technicians, physicists, electricians and construction workers. It was a complex task that was completed without incident due to a strong culture of safety.

Last March, a new beam line opened at the Stanford Synchrotron Radiation Laboratory (SSRL), thanks to three years of work by the Beam Line Development Group and about 50 designers, technicians, physicists, electricians and construction workers. It was a complex task that was completed without incident due to a strong culture of safety.

"There were many factors to consider in this project, including extreme technical demands, precision work, and tight space and schedule constraints," said Beam Line Development Group Engineering Physicist Dan Harrington. "But for us, above all was safety. We were successful because we planned and orchestrated each step carefully, with each person working on the project dedicated to safety."

The first phase of the project was designing the beam line in such a way that the containment shielding would keep x-rays only where they are wanted, protecting users and staff from accidental exposure. "Every step of the design process included thinking about it from a radiation safety perspective," said Harrington. Throughout the process, the Beam Line Development Group used guidelines developed in concert with the Radiation Physics Group and the Earthquake Safety Committee to ensure that the design maximized safety.

The resulting blueprints aided the development of a detailed construction plan that would expedite the complex project quickly and safely. "We have many talented technicians," said Harrington. "One of these is Dave Wenger, who was responsible for securing the construction area. He also ensured that the 500-pound lead hutch walls were moved and installed safely, with proper attention to environmental controls, and utilizing appropriate personal protective equipment and training."

In addition, the Beam Line Development Group worked with SSRL Facilities Manager Brian Choi to ensure that the outside contractors who installed electrical wiring adhered to safety requirements and guidelines.

"Our team takes responsibility for the safety of themselves and the safety of others in the area," said Harrington. "What's more, one of the reasons this project was such a success is that we orchestrated it carefully. We couldn't have lead walls being moved while electricians were installing conduit."

This careful orchestration required several types of safety meetings and forums. At the beginning of every weekly Beam Line Development Group meeting, Group Leader Tom Rabedeau asked if there were any ES&H issues to be discussed. Anything brought up at these meetings was taken very seriously. “Our safety record stems from the care exercised by each individual technician both from SLAC and the external contractors as well as the careful coordination of activities between the various groups involved,” emphasized Rabedeau. Frequent meetings between the various groups ensured that everyone understood not only their own responsibilities, but also knew what other groups would be doing. Plus, Harrington met with installation technicians on a daily basis to ensure that any last-minute questions could be answered.

"It's a dance you have to synchronize," said Harrington. "But with effort, we completed a complex project in a confined area successfully and safely."

—Kelen Tuttle, SLAC Today, June 12, 2007